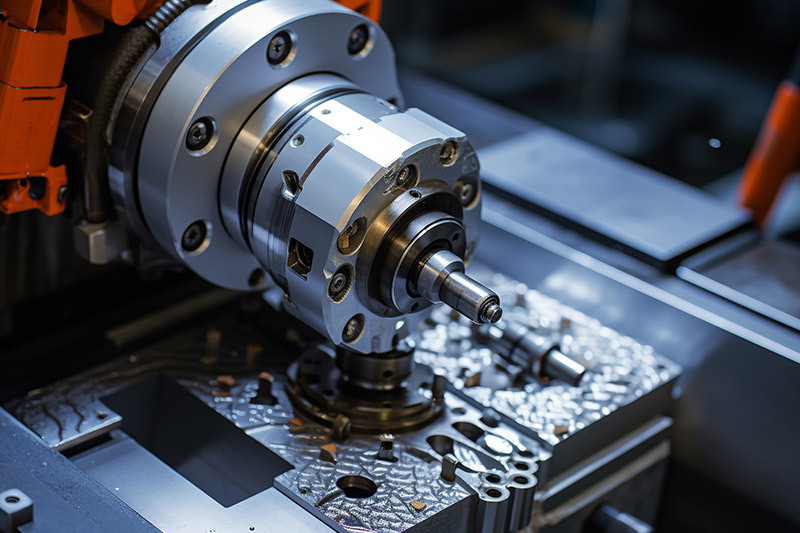

Breakthroughs and progress in standards and quality work

With the deepening of machine tool industry standards and quality construction work, the industry has made breakthroughs and progress in standard upgrading and quality improvement in 2020. In January 2020, the ISO10791-7 standard revised under the auspices of China: 2020 "Test conditions formachining centres-Part7: Accuracy of finished test pieces (Inspection Conditions for Machining Centers Part 7: Precision Inspection of Finishing Specimens)" was approved and officially released by the International Organization for Standardization (ISO), and the "S-specimen" five-axis machine tool inspection method officially became the international standard. In May 2020, the "CNC Machine Tool Interconnection Communication Protocol Standard (NC-Link) and Test Verification Project" organized by the China Machine Tool Industry Association passed the acceptance and formed the association group standard, establishing a unified standard for the interconnection of CNC machine tools in China, which will promote the construction of intelligent factories and intelligent workshops. In September 2020, the China Machine Tool Industry Association group standard "Vertical Machining Center Product Quality Evaluation Specification" entered the test verification stage, and the other four group standards were included in the 2020 Association Group Standard Development Plan.

recommend News